Gf1730 170x300mm g10 fr4 epoxy resin sheet glass fiber board plate 0 5 1 5 2 3mm raw materials fabrics fibers textiles 3mm 1 x glass fibre sheet 5 0 out of 5 stars 1 20 40 20.

G10 fibreglass sheet nz.

G10 fr4 has extremely high mechanical strength good dielectric loss properties and good electric strength properties both wet and dry.

The fibreglass shop is now 100 online.

We have many different types of finishes for our panels ranging from an xm0 through to a xm2 finishes we also have many a variety of core.

All our panels are made to the customer wishes for both size and finish.

It has characteristics of high strength excellent electrical properties and chemical resistance not only at room temperature but also under humid or moist conditions.

It is available in sheet rod and block form.

Visit our showroom or call for friendly sound advice.

To help us serve our online customers more efficiently we no longer have a walk in store.

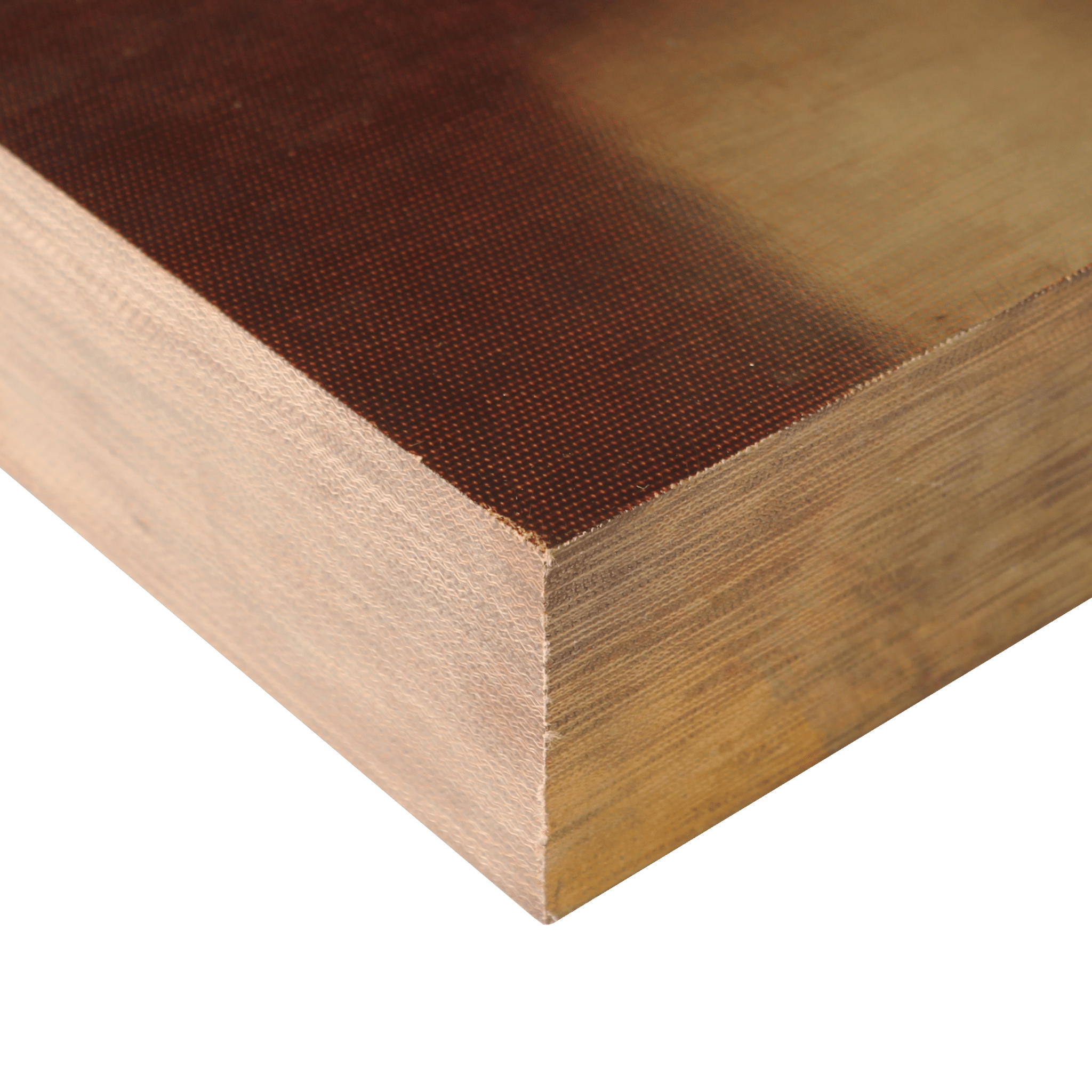

It is made with glass fiber and epoxy which is compressed under extremely high pressure and heat cured to provide an extremely tough and durable material.

Talk to us today we re always ready to assist and help our customers find a solution.

We produce these in both solid colors and multicolored layering.

We offer a comprehensive range of walkway surfaces modular handrails and machine guarding and anti slip products that improve workplace safety and performance.

G10 fiberglass sheets colored fiberglass sheets made from layers of fiberglass and epoxy resin pressed together under enormous pressure and heat.

Overview of g 10 fr 4 sheets g 10 fr 4 is a thermosetting industrial laminate consisting of a continuous filament glass cloth material with an epoxy resin binder.

The main difference between nema grades g10 and fr4 is that fr4 is a fire retardant grade of g10.

New zealand fibreglass ltd supplies retail trade customers with the full range of fibreglass urethane equipment materials technology and advice to make your project a success.

Micarta is a thermoset industrial laminate which is made by applying heat and pressure to layers of paper linen canvas or glass cloth which have been impregnated with either phenolic or epoxy resins this heat and pressure causes a chemical reaction which transforms the separate layers into a single laminated material which cannot be softened hence thermoset.

Here at fibreglass developments we have new zealand s largest flat mould which gives us the upper edge in making larger size panels.

We are new zealand s leading supplier of composite dispensing equipment with glascraft graco binks poly craft svenic prestec akpa.

This material is very light but also very strong and stable.